Types Of Plant Layout Ppt - Some of the important types of plant layout are. Product Layout Here the position of a particular machine is determined at some definite stage or place where the machine is required to perform some operation from a sequence of operations designed to manufacture the product.

Plant Layout Ppt By Me

Plant location layout.

Types of plant layout ppt. Types of Plant layout Functional Layout Process Layout Line Layout Product Layout Static Product Layout Fixed Position Group Layout Cellular Layout Combination layout Hybrid Layout. Plant layout ppt by me 1. The selection of a particular layout relies on many factors.

Plant layout ppt by me. Mostly grouping is employed on different product lines. Product or line layout B.

Fixed layout Product Layout In this type of layout the machines and equipments are arranged in one line depending upon the sequence of operations required for the product. Types of Layouts in industries - Generally there are 5 types of layouts that are widely in usage by industries They are - 1. Minimize investment in equipment Minimize overall production time Utilize existing space most effectively.

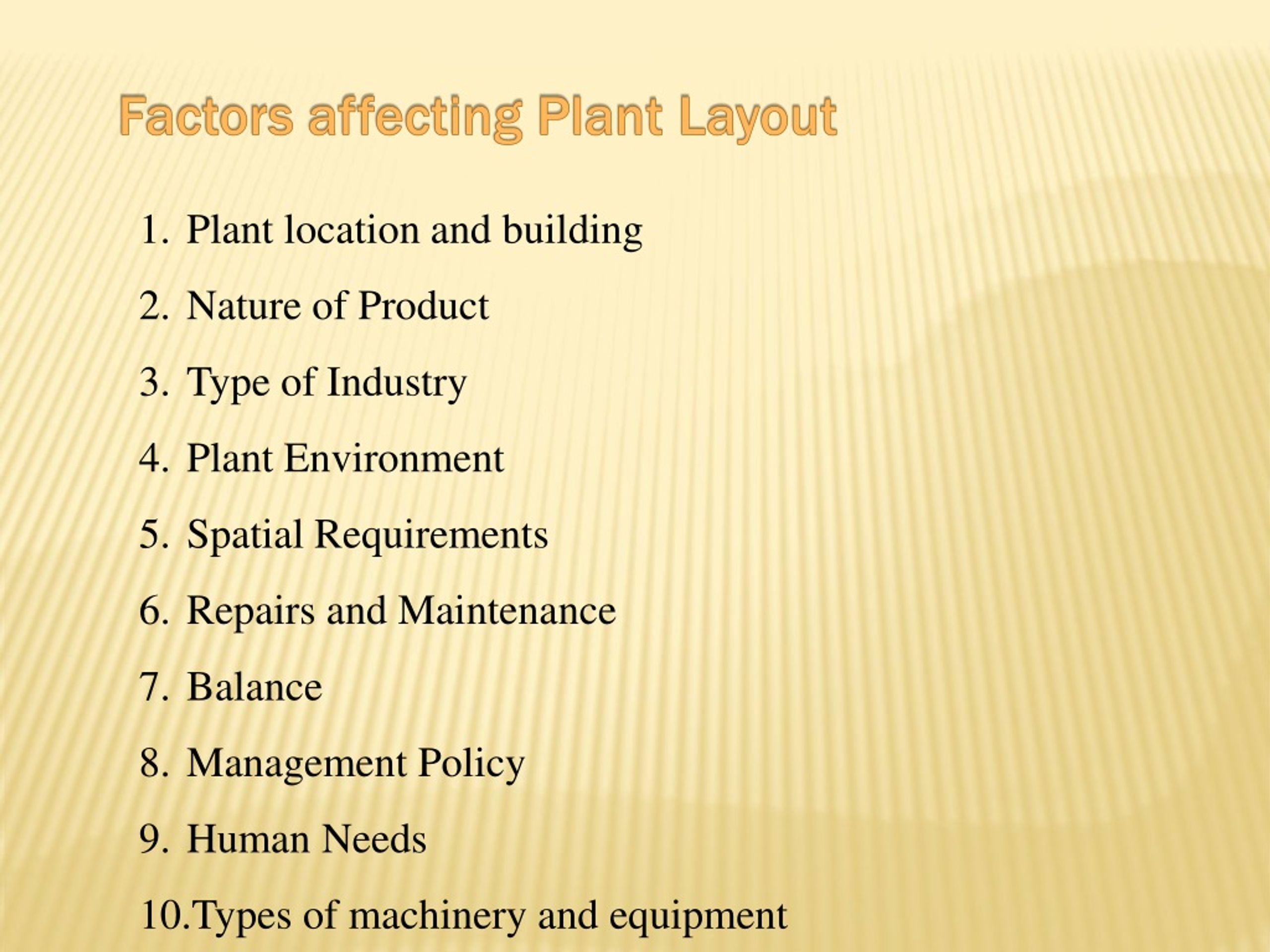

The only other alternative is a combination of product and process layouts in the same plant. Process layout Hybrid Layout. An entrepreneur must possess an expertise to lay down a proper layout for new or existing plants.

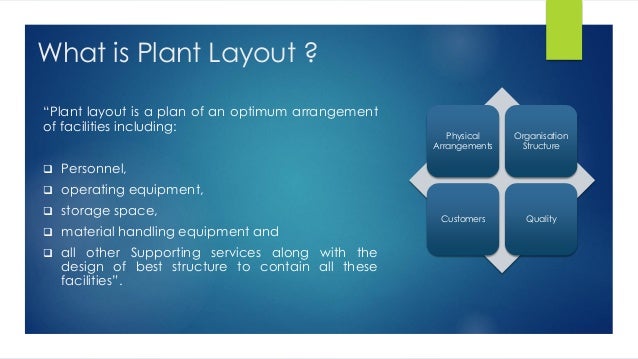

Intermittent processing systems low volume of many different products Continuous processing systems high volume of a few standardized products Types of Layouts Four basic layout. An optimum ar rangement of facilities including. Product or Line Layout is the arrangement of machines in a line not always straight or a sequence in which they would be used in the process of manufacture of the product.

Personnel operating equipment storage space material handling eq uipment and all. It is also called as line layout. This type of layout is used only in cases where services are organised in a sequence.

Process or functional layout C. Two basic plans of the arrangement of manufacturing facilities are product layout and process layout. These layouts are highly common in service facilities as they successfully deal with the varied customer processing requirements.

Production Plant Layout 2 Reasons. There are mainly four types of plant layout. Types of layouts.

Improve productivity TYPES OF LAYOUT. Types of Plants Layout Product layout Process or functional layout Fixed layout 8. PLANT layout is a floor plan of the physical facilities which are used in production.

Boiler Steam Trapes Insulation and Steam Distribution System. Systematic Layout Planning SLP. Layout by stationary material.

Ad Download 100s of Presentations Graphic Assets Fonts Icons More. 3 Nature of the product. Production Process Types of Layout.

New products changes in demand changes in product design new machines bottlenecks too large buffers too long transfer times Design Production Plant Layout 3 Goals examples. Minimal material handling costs minimal investments minimal throughput time flexibility efficient use of space Production Plant Layout 4 Restrictions. It differs from plant to plant from location to location.

A Product or line layout b Process or functional layout c Fixed position or location layout d Combined or group layout. According to Kumar 2013 plant layout is a plan of. TYPESCLASSIFICATION OF PLANT LAYOUTS A plant layout mainly deals with the arrangement and grouping of machines which are used for producing goods.

Process layout Functional layout Job-shop layout. Process LAYOUT is used when the volume of production of a product is high such that a separate production line can be justified. Objectives OF PLANT LAYOUT are.

A Product or Line Layout. Types of Plant Layout Process oriented plant layout Detailed layout Equipment and machinery layout within each area or department getting a detailed layout of installations and all elements. With in the factory building in such a manner so as to have quickest flow of material at the lowest cost and with the least amount of handling in processing the product from the receipt of material to the shipment of the finished.

Service facility layouts areoften categorised under three heads which. Layout planning is deciding the best physical arrangement of all resources within a facility Facility resource arrangement can significantly affect productivity Two broad categories of operations. Types of Plant Layout.

734 TYPES OF LAYOUT As discussed so far the plant layout facilitates the arrangement of machines equipment and other physical facilities in a planned manner within the factory premises. Nature of the commodity or article to be produced greatly affects the type of layout. PLANT LAYOUT Plant layout refers to the arrangement of physical facilities such as machinery equipment furniture etc.

Fixed Position Layout Let us know study of each layout. Types of Plant Layout Process oriented plant layout Analysis Qualitative criteria. Topography shape climate conditions and size of the site selected will influence the general arrangement of the layout and the flow of work in and out of the building.

Location of a plant greatly influences the layout of the plant.

Plant Layout

Plant Layout

Facility Planning Layout Process Ppt

Plant Layout Ppt By Me

Facility Layout Planning Ppt Download

Plant Layout Pdf Inventory Economic Sectors

Plant Layout Powerpoint Slides

Ppt Chapter 5 Plant Design Contents Chemical Engineering Plant Design Sequence Of Steps In Developing A Project Plant Locat Powerpoint Presentation Id 1384568

Plant Layout Powerpoint Slides

Plant Layout And Its Types

Ppt Plant Layout Powerpoint Presentation Free Download Id 338402

Types Of Plant Layout Authorstream

Plant Layout The Plant Refers To The Physical Components Of The Manufacturing Process Of The Product Required Both In Terms Of Buildings And Equipments Ppt Download

Plant Layout And Its Types