Ultrasonic Welding Nptel - NPTEL provides E-learning through online Web and Video courses various streams. This section covers two classifications related to weld joints.

Ultrasonic Welding Video Lecture By Prof Prof Dheerendra Kumar Dwivedi Of Iit Roorkee

Ultrasonic Machining is a non-traditional process in which abrasives contained in a slurry are driven against the work by a tool oscillating at low amplitude 25-100 microns and high frequency 15-30 kHz.

Ultrasonic welding nptel. R S Parmar Welding process and technology Khanna Publisher New Delhi. R S Parmar Welding process and technology Khanna Publisher New Delhi. 36Weldability of aluminium alloys.

Ultrasonic welding is used for both soft and rigid thermoplastics and for thermoplastic composites. UNIT-IV Explosive welding cladding etc. Ultrasonic machining is a mechanical type non-traditional machining process.

H Cary Welding Technology Prentice Hall 1988 2nd edition. Ii Welding Handbook Ninth Edition Volume 1 Welding Science and Technology. Ultrasonic welding is the fastest known welding technique with weld times of less than 1 s.

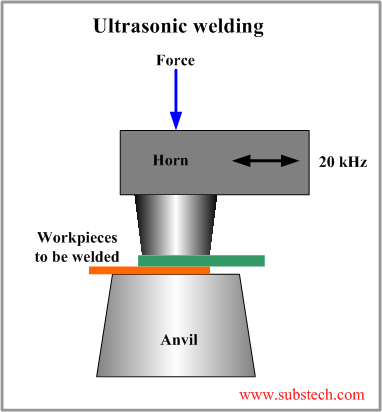

Components necessary for ultrasonic welding are a generator or power supply a converter or transducer booster and a horn or sonotrode see Fig. Principle and working and applications of unconventional welding processes such as laser beam welding electron beam welding ultrasonic welding plasma arc welding. Under water welding metallising.

Ultrasonic welding is an industrial technique whereby high- frequency ultrasonic acoustic vibrations are locally applied to work pieces being held together under pressure to create a solid- state weld. A press to put the two parts to be assembled under pressure A nest or anvil where the parts are placed and allowing the high frequency vibration to be directed to the interfaces An ultrasonic stack composed of a converter or piezoelectric transducer an optional booster and a sonotrode us. 141 Fusion welding without pressure 02 142 Pressure welding 02 143 Non-fusion welding 03 15 CLASSIFICATION OF WELDING PROCESSES ACCORDING TO HEAT 03 16 CODES FOR WELDING PROCESSES 04 17 APPLICATIONS OF VARIOUS WELDING PROCESSES 04.

Welding technologies are of critical importance for the construction of virtually all components of the assemblies. 35Metallurgical transformations in weld and heat affected zone of steels. This includes physics of electric arc-plasma engineering the arc-plasma for welding.

It begins when the parts that are to be welded such as two multi-strand copper wires for example are placed together in the welding unit. H Cary Welding Technology Prentice Hall 1988 2nd edition. This is a type of spot welding the evolution of screwing technology suitable for those components which dont need for simultaneous welding joining of the entire welding path.

Application of advanced welding technique like friction laser. CERTIFICATION EXAM The exam is optional for a. In addition to all of the uses of ultrasonic in the welding of metals the technology can also be used to weld plastic parts together.

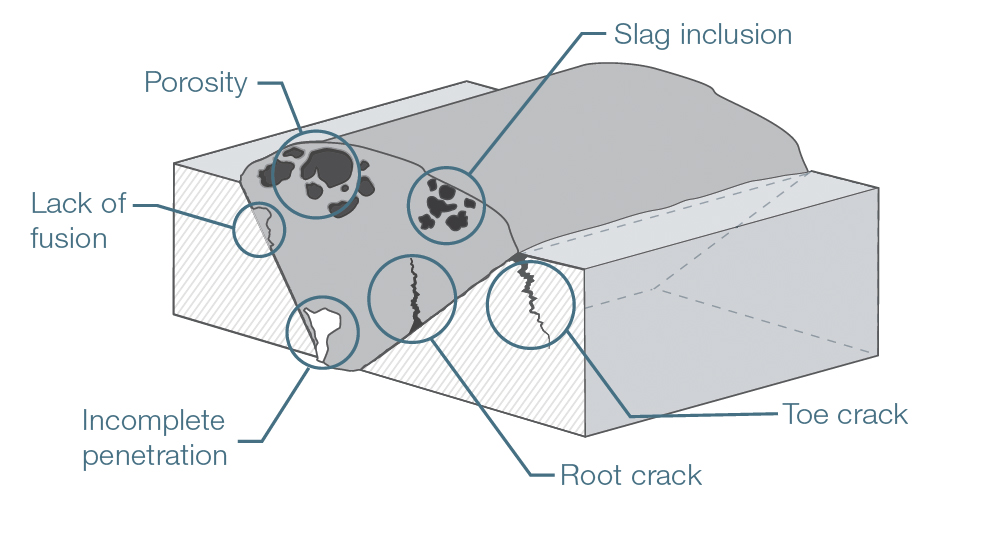

A weld joint is the junction of the edges or surfaces of parts that have been joined by welding. UNIT-III Unconventional welding process. 4- TYPES OF JOINTS.

NPTEL provides E-learning through online Web and Video courses various streams. LeJeune Road Miami FL 33126. Components All ultrasonic welding systems are composed of the same basic elements.

Ultrasonic Welding is a plastics welding process in which two work pieces are bonded as a result of a pressure exerted to the welded parts combined with application of high frequency acoustic vibration ultrasonic. 31Solidification of weld metal. Ultrasonic welding is an industrial process whereby high-frequency ultrasonic acoustic vibrations are locally applied to workpieces being held together under pressure to create a solid-state weldIt is commonly used for plastics and metals and especially for joining dissimilar materialsIn ultrasonic welding there are no connective bolts nails soldering materials or adhesives.

32Fundamentals of weldability of metals. But when the ultrasonic inspection of the welds point. 30Heat affected zone and weld thermal cycle.

Center for Lightweight Production Technology ZLP AugsburgThe video shows an end-effector for continuous ultrasonic welding which was developed and build by. Machining ultrasonic machining abrasive jet machining etc. Mechanized underwater welding for actual Investigation of the potential of using a robot manipulator for underwater ultrasonic testing of welds in joints of complex geometry.

34Weldabiliity of stainless steels. S V Nadkarni Modern Arc Welding Technology Ador Welding Limited 2010 New Delhi. Welding Handbook Ninth Edition Volume 1 WELDING SCIENCE AND TECHNOLOGY Prepared under the direction of the Welding Handbook Committee Cynthia L.

How Ultrasonic Welding works The process of ultrasonic welding is fairly simple. The ultrasonic welding process is based on the conversion of friction and vibration energy into heat. Welding produces a solid connection between two pieces called a weld joint.

Ultrasonic welding technology was invented and patented in the early 1930s and was originally used for the solid-state welding of metals 41. R S Parmar Welding process and technology Khanna Publisher New Delhi Welding handbook American Welding Society 1987 8th edition volume 1 2 USA Certification Exam The exam is optional for a fee. 33Weldability of carbon and alloys steels.

Welding handbook American Welding Society 1987 8th edition volume 1. Most modern joining welding technologies. H Cary Welding Technology Prentice Hall 1988 2nd edition.

Richard Little Welding and Welding Technology McGraw Hill 2001 1st edition. Jenney Annette OBrien Editors American Welding Society 550 NW. This course aims to elaborate the physical principles of arc plasma laser resistance spot electron beam and solid state welding processes.

Ultrasonic flaw detection in weld inspection is commonly used in non-destructive testing methods. S V Nadkarni Modern Arc Welding Technology Ador Welding Limited 2010 New Delhi. S V Nadkarni Modern Arc Welding Technology Ador Welding Limited 2010 New Delhi.

1 types of joints and 2 the types of welds used to join the pieces that form the joints. First - Ultrasonic assembly uses ultrasonic vibratory energy which is transmitted through the parts to melt and bond. Topics covered in this course include manufacturing systems and trends evaporative pattern casting processes shell mold process abrasive flow machining abrasive jet machining ultrasonic machining process electro discharge machining process laser beam machining electrochemical machining and advanced welding processes.

Ultrasonic vibration transmitted by a metal tool horn sonotrode causes oscillating flexing of the material and friction between the parts which results in a.

2

Classification Of Welding Processes I Youtube

.jpg)

Noc Joining Technologies For Metals

Solid State Welding Processes Advantages And Disadvantages

Advances In Welding And Joining Technologies Week 7 Nptel Youtube

2

.jpg)

Noc Joining Technologies For Metals

Noc Joining Technologies For Metals

Cnc Programming

A Fast Safe Alternative For Weld Inspections Olympus Ims

Nptel Metallurgy And Material Science Noc Welding Processes

Cnc Programming

2

Ultrasonic Processing Substech